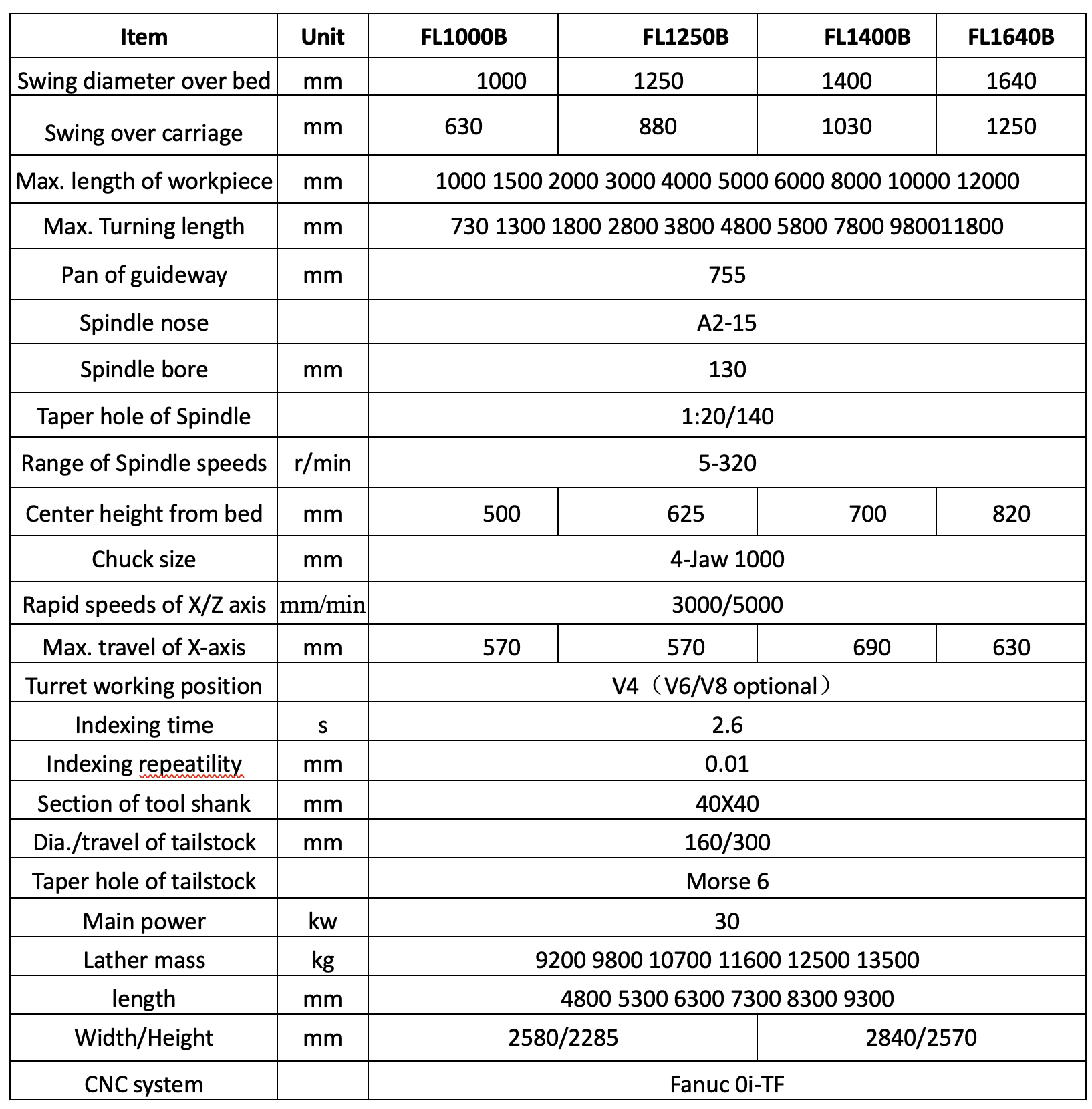

Flat bed lathe

Main structural features:

1. Bed body: integral box structure, made of high standard cast iron (HT300) secondary molding casting, with a guide rail surface width of 755mm;

2. Spindle box: able to adapt to heavy cutting processing, gears undergo high-frequency quenching and precision grinding, with high precision, smooth operation, and low noise; The spindle has a large diameter and is supported by precision heavy-duty bearings in a three-point manner, ensuring stable rotation. It can be used for both heavy cutting and precision turning; It can achieve continuously variable speed and constant linear speed cutting.

3. Feed: Precision grinding grade ball screw pairs are used in the X and Z directions to ensure high machining accuracy, positioning accuracy, and accuracy retention; Each pair of motion is automatically lubricated by a centralized intermittent lubrication system; Longitudinal (Z-direction) feed: 1000-6000 specifications are fed by an AC servo motor installed on the left side of the feed box through a high-precision planetary reducer to drive the screw feed, while specifications above 6000 are fed by gear rack transmission; Machine tools have high positioning accuracy and repeatability.