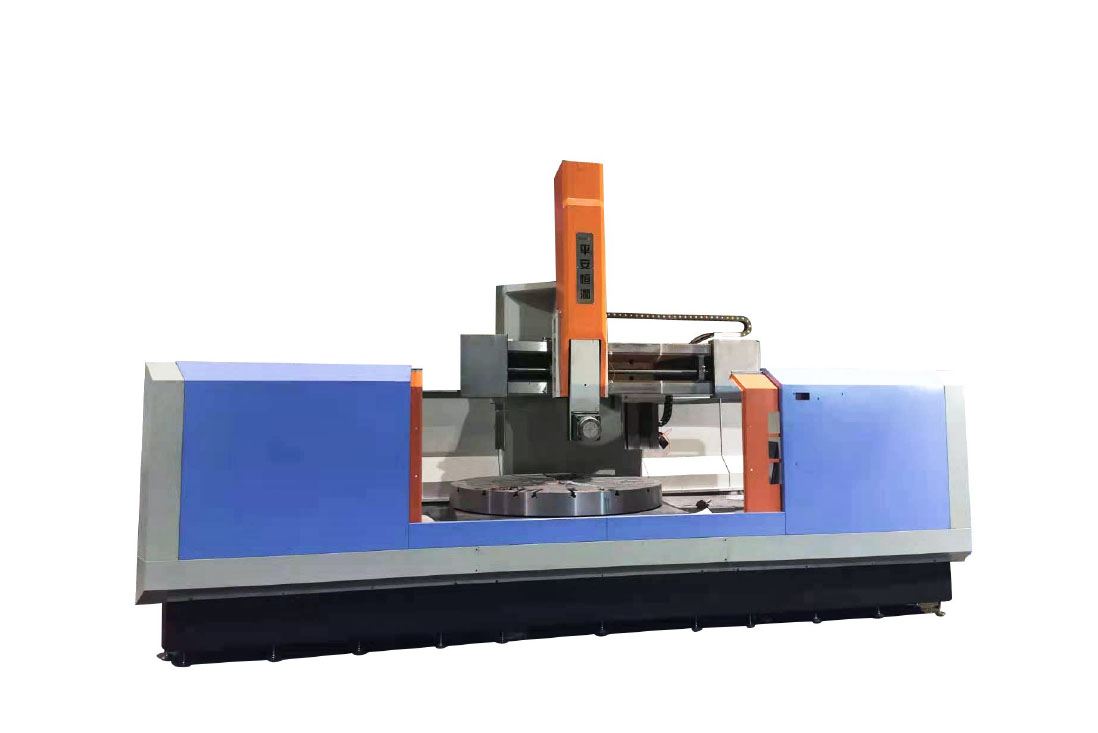

Vertical lathe

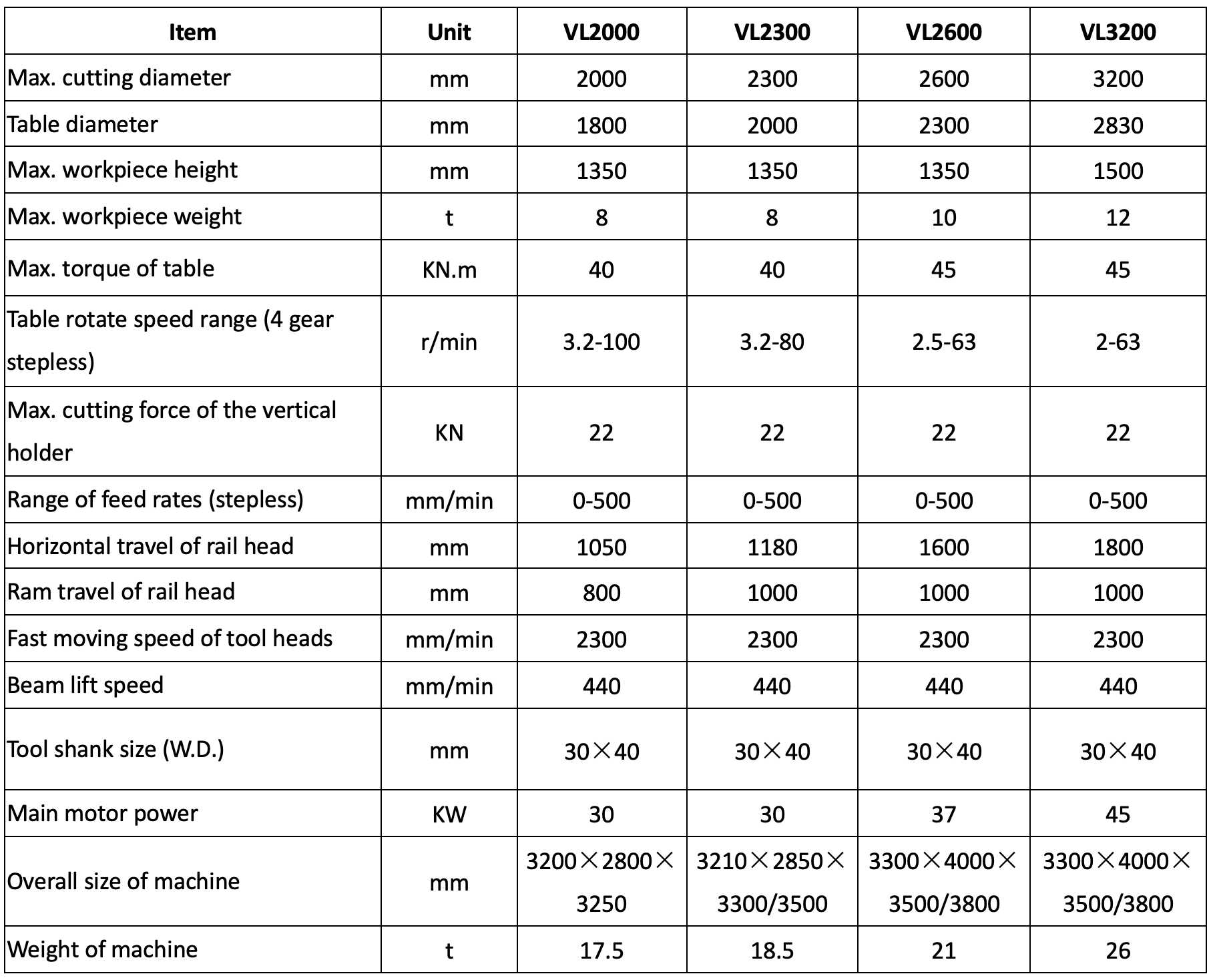

According to customer requirements, spindle servo motors and spindle encoders can be equipped to achieve threading and constant linear speed cutting functions.

The worktable spindle adopts high-precision adjustable radial clearance double row short cylindrical roller bearings for centering. The axial direction adopts a constant current static pressure guide rail, which makes the worktable have the characteristics of high rotation accuracy, large bearing capacity, and small thermal deformation.

The base, workbench, bed, crossbeam and other large components are made of high-strength and wear-resistant gray cast iron and treated to eliminate internal stress and prevent deformation.

The guide surfaces of the bed, crossbeam, and slide pillow are quenched, ground, and manually combined for good contact and high precision. The crossbeam is equipped with hydraulic time locking, which allows for a large amount of cutting without shaking.