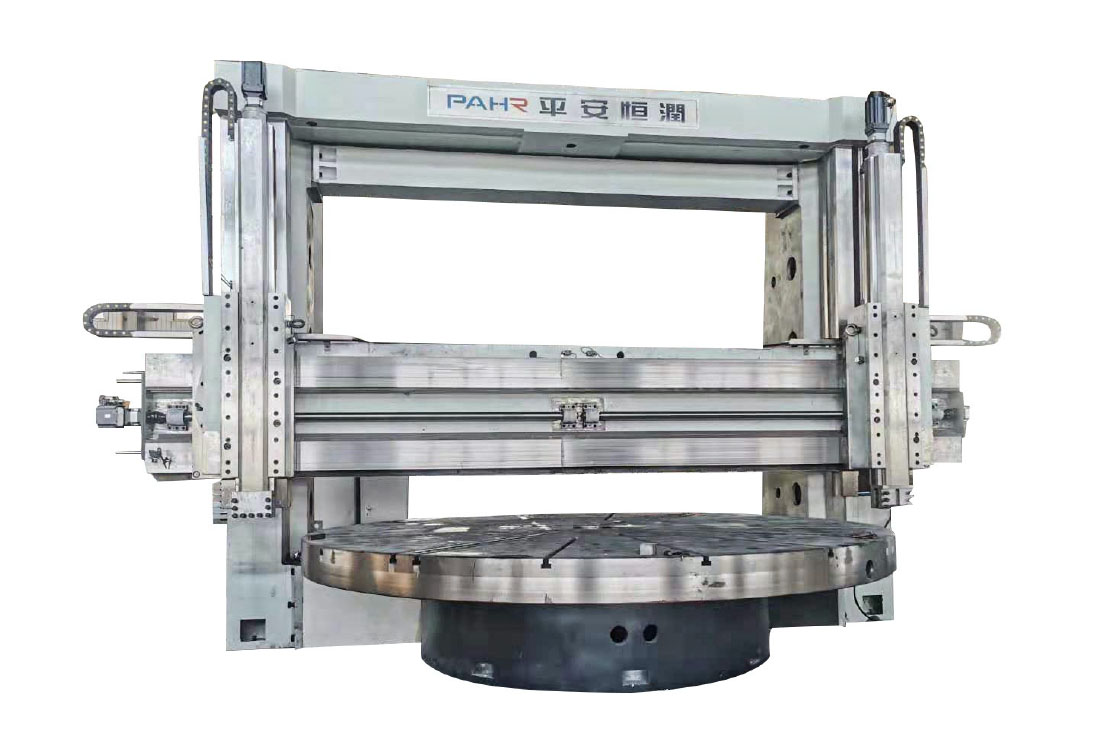

Vertical lathe

The main drive of the machine tool is divided into two types: AC and DC motor drive. The communication passes through a 16 level spindle speed change mechanism, and the DC passes through a two speed change mechanism to achieve the speed range of the worktable.

The worktable spindle adopts high-precision adjustable radial clearance double row short cylindrical roller bearings for centering, and the worktable adopts constant current static pressure guide rails, making the worktable have the characteristics of high rotation accuracy, large bearing capacity, and small thermal deformation.

According to user needs, the machine tool can be equipped with a constant temperature cooling device and an independent hydraulic station system, which can ensure the machining accuracy and stability of various technical indicators of the machine tool.

The guide surfaces of columns, beams, and sliding pillows are quenched, ground, and manually combined for good contact and high precision.

The machine tool feed adopts servo motor and ball screw transmission, and the crossbeam is equipped with a closed cover, which increases the safety and comfort of the machine tool.

The CNC system can be equipped with imported or domestic configurations according to user needs.

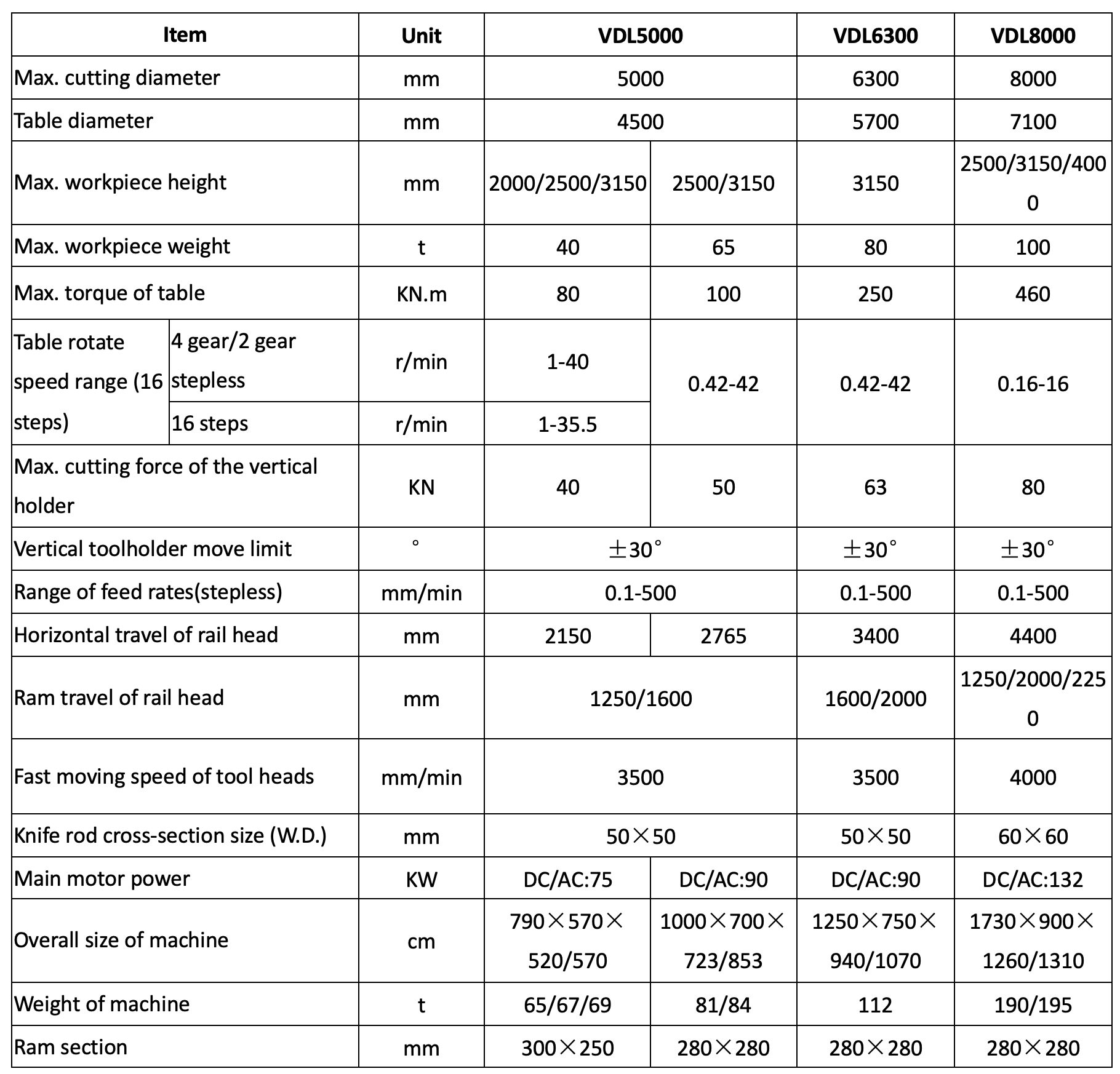

Select configuration: electric cutting table, semi enclosed casing, cooling chip removal device, and two speed stepless speed regulation.