Electrical spark hole processing machine

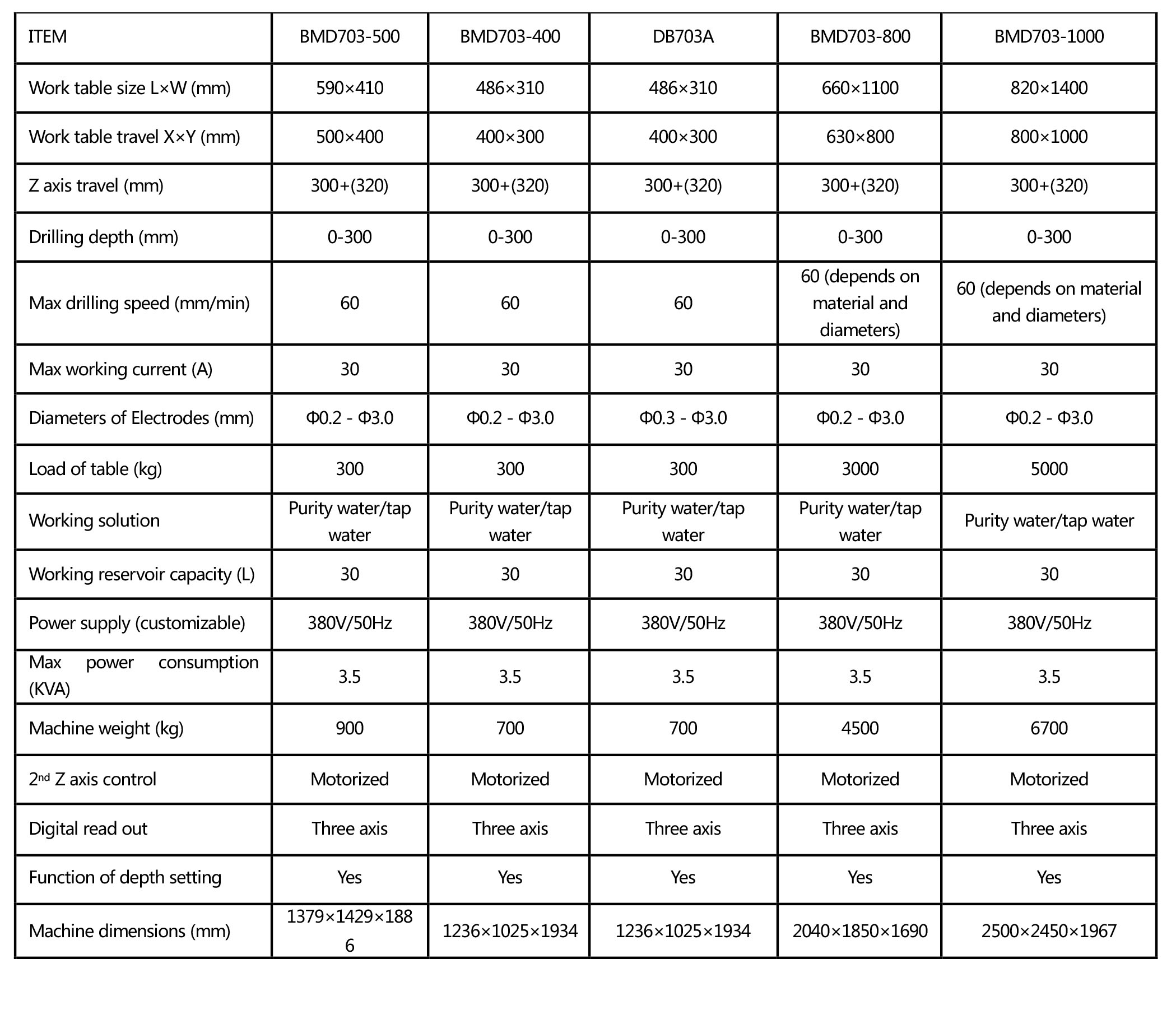

The punching machine programming and control system developed by Baoma has complete intellectual property rights. It works in a time-sharing manner and can simultaneously draw and program during processing; The high-speed electric discharge perforating machine uses electrode tubes (brass tubes, copper tubes) as tool electrodes, utilizing the principle of electric discharge erosion. A high-frequency pulse power supply is applied between the electrode (hollow copper tube) and the work to form a small pulse width, high peak current discharge machining, supplemented by high-pressure water cooling to remove slag, greatly accelerating the erosion speed of the workpiece. It is particularly suitable for processing deep small holes with diameters between Φ 0.2 and Φ 3.0 on various conductive materials such as stainless steel, quenched steel, copper, aluminum, hard alloys, etc., with a depth to diameter ratio of up to 300:1. It can directly enter the processing on the inclined and curved surfaces of the workpiece. This machine is mainly used for threading holes, chemical fiber wire spraying heads, wire spraying holes of wire spraying plates, filter plates, and screen plates in electric discharge wire cutting machining. Holes, engine blades, heat dissipation holes in the cylinder block, oil and air passage holes in hydraulic and pneumatic valve bodies, etc. It can also be used to remove broken drill bits, taps, etc. in workpieces without damaging the original holes into threads.